Songjia Town, Lingcheng District, Dezhou City, Shandong Province, China [email protected] +86-15069278821

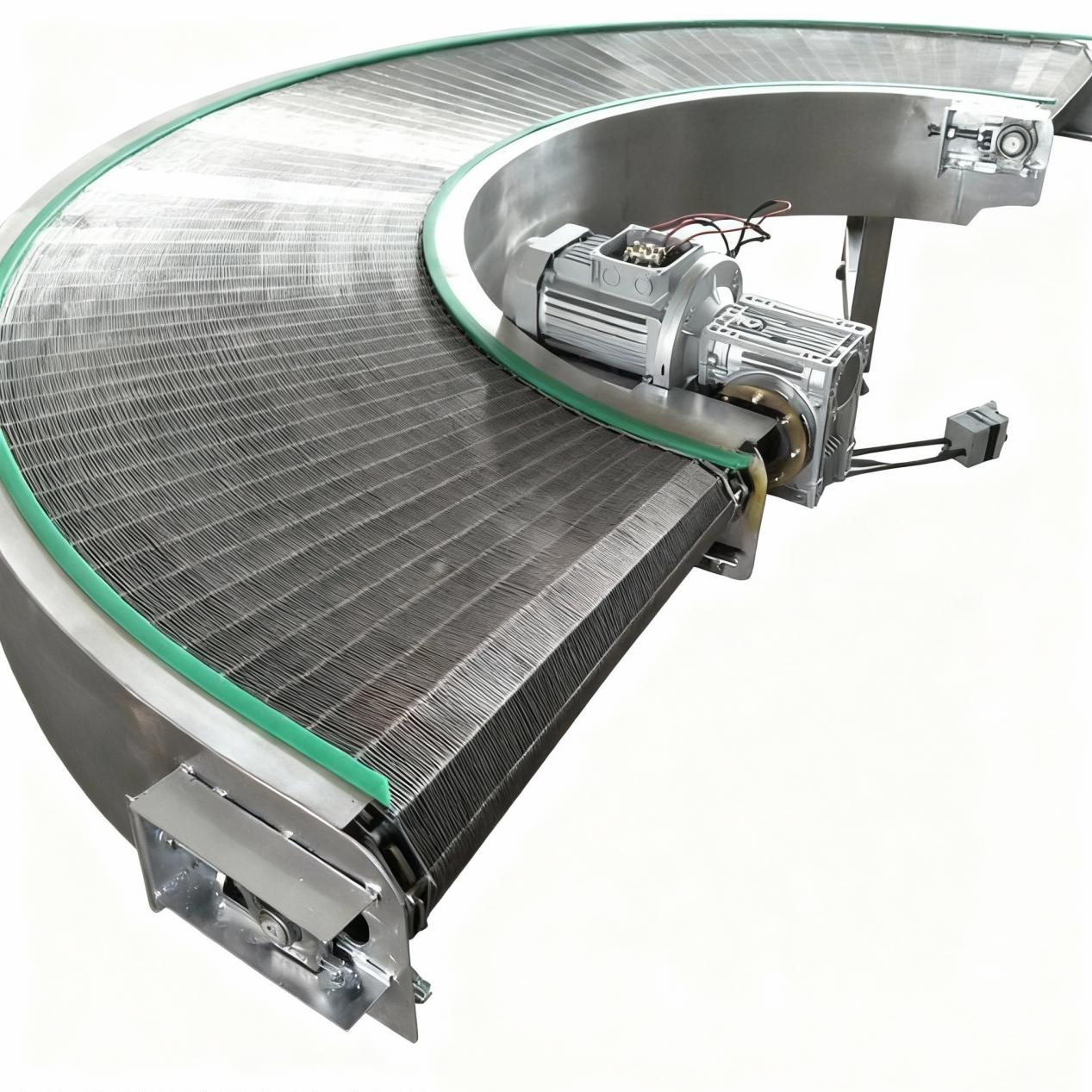

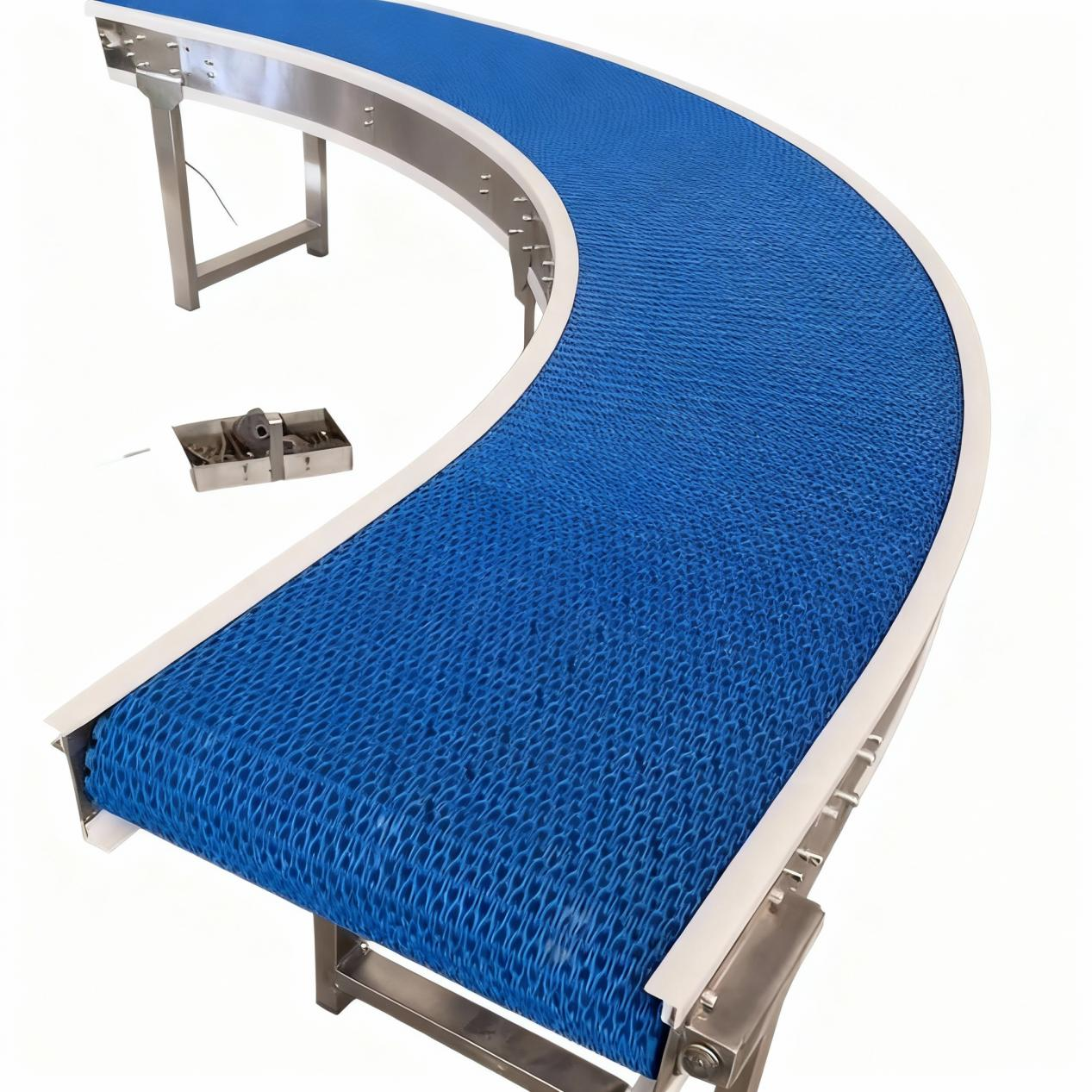

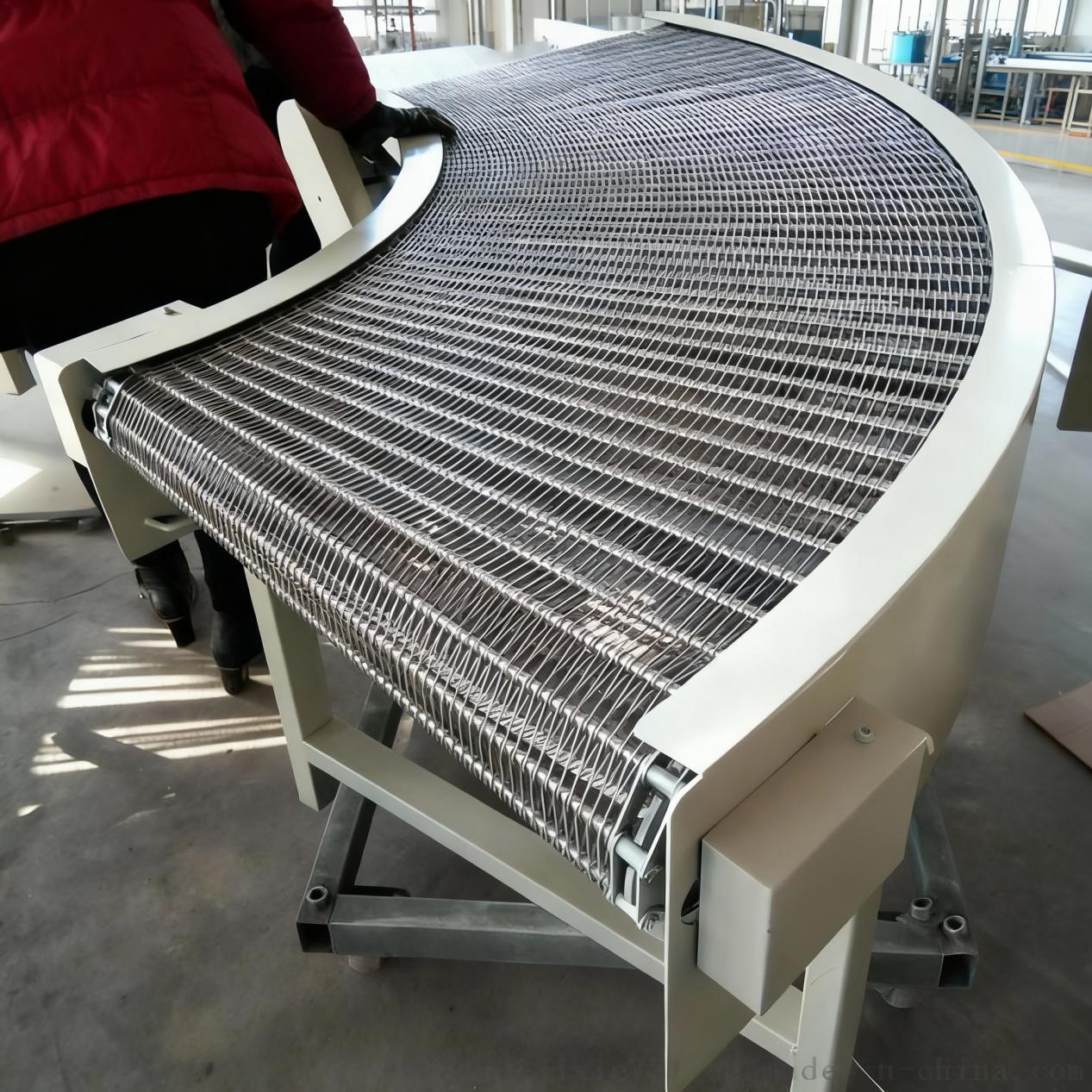

The turning mesh belt conveyor is mainly used in the production line, which is a special conveyor with the function of linking. It has the advantages of flexibility and easy to connect with other conveyor equipment in the production line.

The turning mesh belt conveyor is mainly used in the production line, which is a special conveyor with the function of linking. It has the advantages of flexibility and easy to connect with other conveyor equipment in the production line.

The turning conveyor is widely used in the production of enterprises. In the conveying operation, we often see the role of this conveyor. The main types include: turning belt conveyor, turning mesh belt conveyor, turning chain plate conveyor, turning drum conveyor, etc.

The turning mesh belt conveyor system can be customized with various turning angles to meet specific client requirements. The primary configurations include: 360-degree, 270-degree, 180-degree, 90-degree, and 45-degree curved conveyors. These specialized units are the flagship products of Sunshine Conveying Equipment, with additional capacity for designing and manufacturing other non-standard conveyor systems.

Each client's product has unique characteristics. Therefore, when customizing a turning conveyor belt, customers should provide us with the following parameters based on their specific product requirements:

1. The conveying angle of the turner (e.g., 360°,180°,90°, or 45° turners).

2. Determine whether the turning machine's power system is non-powered or motor-driven.

3. Whether the turning machine operates under special conditions such as high humidity, high temperature, or exposure to chemicals;

4. What is the bottom shape of the item to be conveyed by the turning machine?

5. What is the approximate weight of the items being transported?

6. What are the required dimensions (length, height, and width) for the items to be transported by the turning machine?

When designing and installing a turning mesh belt conveyor, it is essential to ensure the shortest possible transportation route for components. This facilitates close-range operation by production workers and streamlines the workflow of auxiliary service departments. The system should also maximize the utilization of production workshops, warehouses, or storage facilities while considering seamless connections between conveyor installations. To achieve optimal production efficiency, the arrangement method of the turning conveyor must be carefully planned during layout design. This ensures maximum benefits when multiple workstations are involved in a process, while fully complying with the operational workflow.

The transition between the turning belt conveyors should be easy to connect. It can be used to form a complex conveying system and a diversion and confluence system with multiple conveying lines and other conveying equipment or special machines to complete the multi-faceted process needs, which is widely used.

The application scope includes: electronics, beverages, food, packaging, machinery, light industry, tobacco, chemicals, pharmaceuticals, rubber and plastics, automotive and motorcycle, logistics, etc. It is also applicable to various bottled, canned, carton, and barrelled products.

The main materials of the turning mesh belt conveyor are carbon steel, stainless steel and plastic steel.