Songjia Town, Lingcheng District, Dezhou City, Shandong Province, China [email protected] +86-15069278821

• Industrial Production: In industries such as metallurgy, coal, and building materials, it is used to transport raw materials or finished products between workshops on different floors, thereby improving production efficiency. For example, in a metallurgical plant, ore can be lifted from the lower-level warehouse to the upper-level smelting workshop.

• Logistics warehousing: In logistics centers and warehouses, it enables rapid handling and sorting of goods across different floors to accelerate turnover. For instance, in e-commerce warehouses, products can be lifted from storage areas to sorting zones.

• Food Processing: Designed to meet material handling requirements across different floors for various processing stages, with customized manufacturing to comply with food industry hygiene standards.

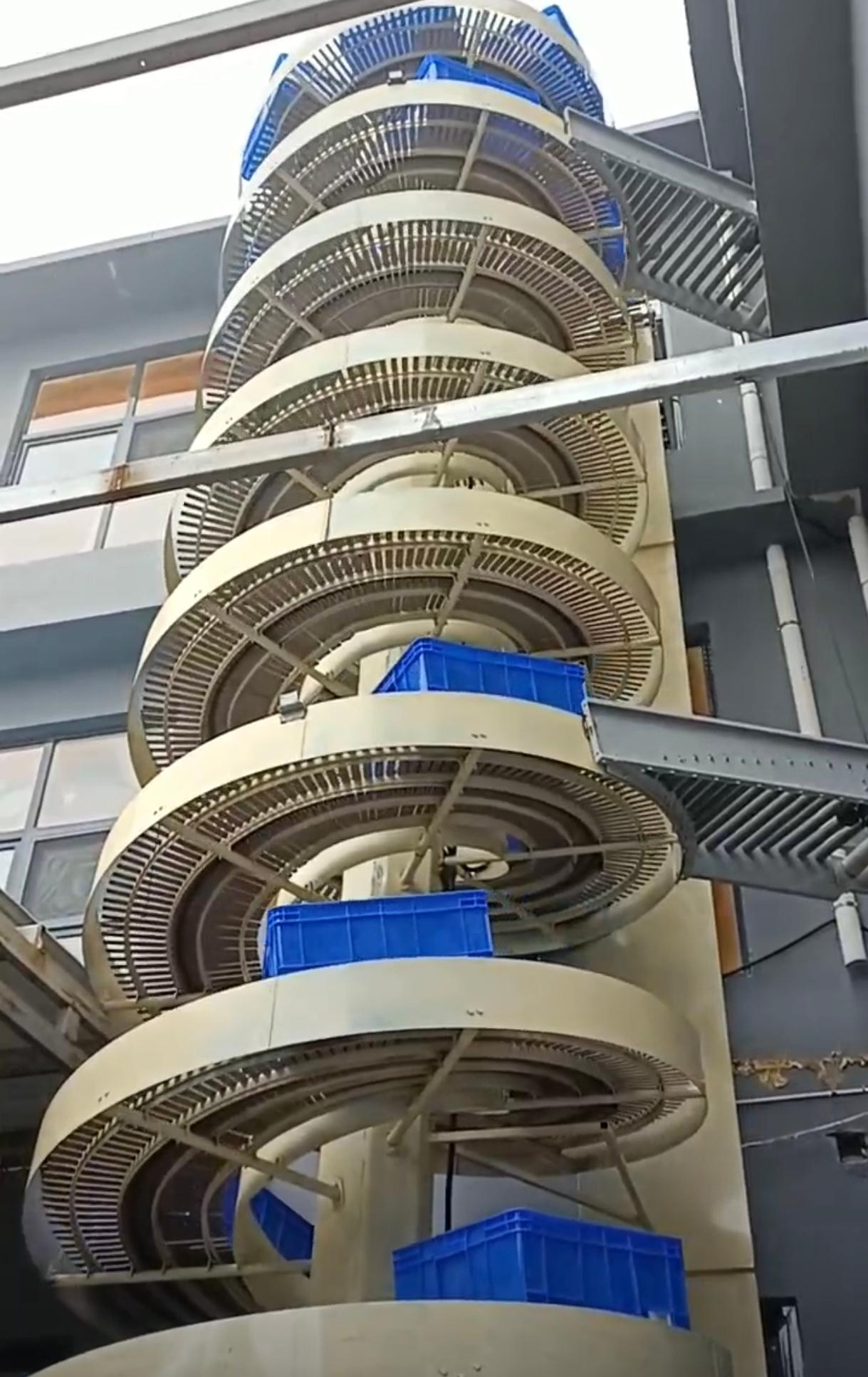

The cross-floor lifting conveyor, which includes a spiral elevator and a cross-floor turning lifting conveyor, is a device designed for vertical material lifting and conveying between different floors. It is widely used in industrial production and logistics transportation.

Common Types and Characteristics:

• Lift Conveyor: Combining vertical lifting and horizontal movement functions, its core structure includes a support frame, lifting mechanism, and drive system. Available in hydraulic-driven and spiral tower vertical models, the hydraulic version supports a maximum load of 2000kg with a conveying capacity of 30t/h and 5.5KW power, while the spiral model achieves a conveying speed of 20 meters per minute. Its modular design enables adaptation to diverse scenarios and supports customized production.

• Vertical Lift Conveyor: Also known as a continuous vertical conveyor or folded plate vertical conveyor, it enables continuous vertical material transportation across different floors. This system can vertically lift and lower powdered, granular, or piece-shaped materials, and can integrate drying, cooling, and other processing workflows. It supports integration with intelligent devices such as AGVs, robotic arms, and warehouse shuttle carts, and can be equipped with MES/WMS management software for task scheduling and real-time monitoring. The system is adaptable to special scenarios like explosion-proof and low-temperature environments.

• Vertical feed conveyor: Designed for efficient vertical transportation of granular materials, featuring a sealed structure to minimize dust emission.

• Scraper chain elevator: This system achieves continuous material transfer through the interplay of scrapers and chains, capable of handling powdery or lump materials with poor flowability.

• Chain Plate Elevator Conveyor: Using metal chain plates as the carrier, it is wear-resistant and highly load-bearing, ideal for vertical lifting of heavy materials.

Application area:

• Industrial Production: In industries such as metallurgy, coal, and building materials, it is used to transport raw materials or finished products between workshops on different floors, thereby improving production efficiency. For example, in a metallurgical plant, ore can be lifted from the lower-level warehouse to the upper-level smelting workshop.

• Logistics warehousing: In logistics centers and warehouses, it enables rapid handling and sorting of goods across different floors to accelerate turnover. For instance, in e-commerce warehouses, products can be lifted from storage areas to sorting zones.

• Food Processing: Designed to meet material handling requirements across different floors for various processing stages, with customized manufacturing to comply with food industry hygiene standards.

Cross-floor lift conveyor size: Custom

Minimum order: 1 unit