Songjia Town, Lingcheng District, Dezhou City, Shandong Province, China [email protected] +86-15069278821

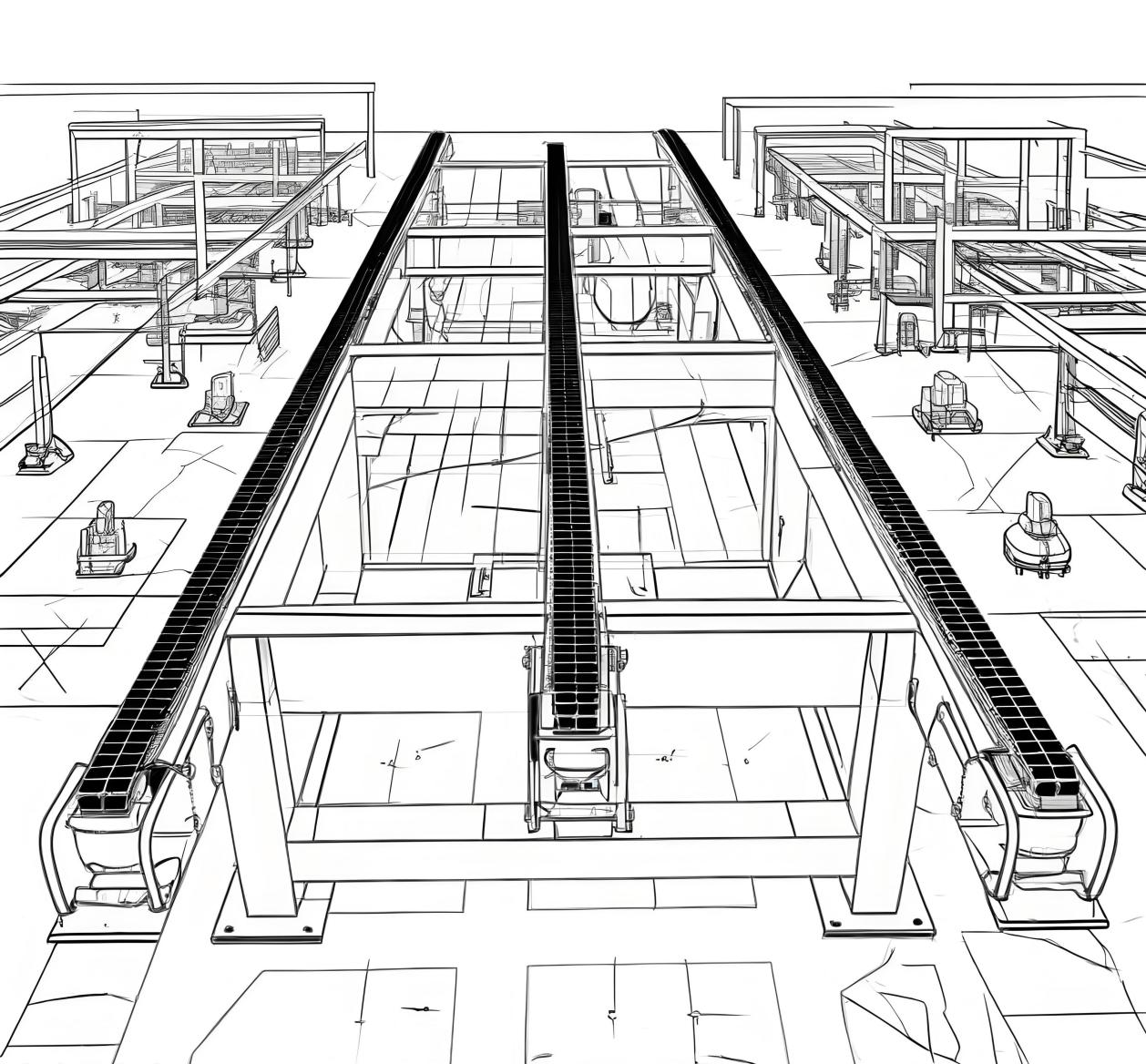

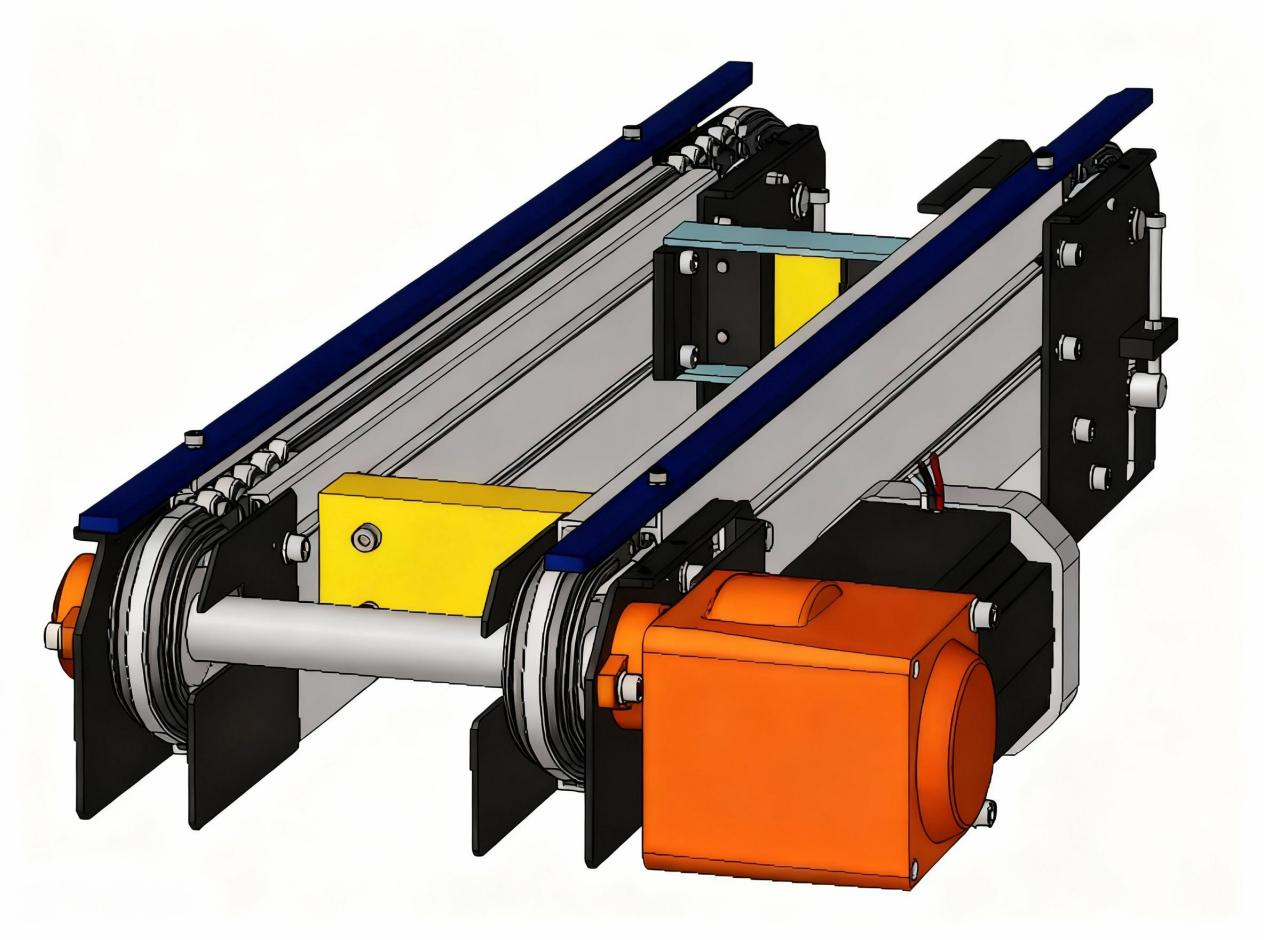

Chain conveyor, also known as speed-increasing chain conveyors or speed-enhancing chain production lines, form a production line commonly referred to as a self-flow conveying system. These systems utilize specially designed, surface-treated extruded aluminum alloy profiles as guide rails, ensuring exceptional stability and durability during material handling. This makes them ideal for continuous mass production of goods. Additionally, the system's flexible and versatile design enables it to serve multiple purposes.

Chain conveyor, also known as speed-increasing chain conveyors or speed-enhancing chain production lines, form a production line commonly referred to as a self-flow conveying system. These systems utilize specially designed, surface-treated extruded aluminum alloy profiles as guide rails, ensuring exceptional stability and durability during material handling. This makes them ideal for continuous mass production of goods. Additionally, the system's flexible and versatile design enables it to serve multiple purposes.

Primarily designed for medium and small-scale assembly, inspection, aging, and conveying operations, this system allows fixture installation on tooling plates to meet workpiece assembly requirements. It is widely used in the assembly, component assembly, inspection, and debugging of medium and small household appliances. The speed-adjustable chain conveyor, equipped with elevators for material handling, enables dual-layer and multi-layer conveying, achieving both transportation and storage functions.

1. Product Features:

2. Parameters of chain conveyor:

Device Features: Speed Regulation, Energy Efficiency, Stable Operation